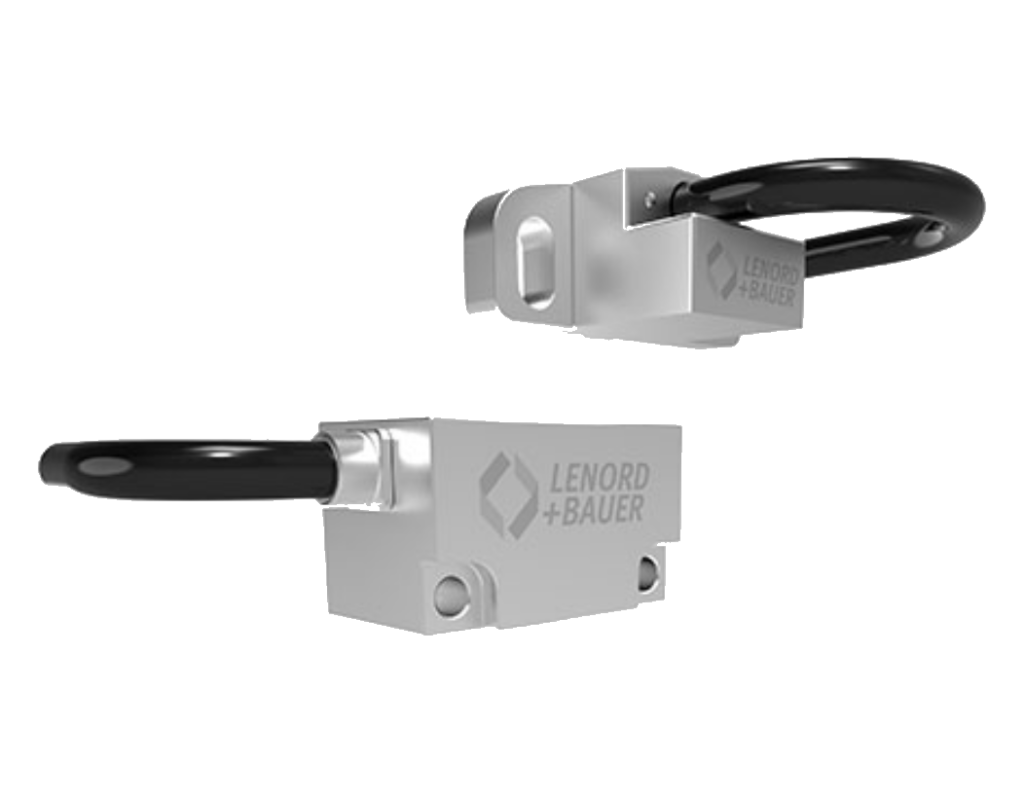

GEL-244xm Configurable MiniCODER

A compact, configurable speed and position encoder with a high-speed Mitsubishi serial interface; contactless magnetoresistive sensing gives reliable rotation direction, speed and position data for CNC and industrial automation.

Key Features

📈 High-resolution position and speed detection (up to 26 bit)

Precise, high-bit resolution feedback for accurate motion and speed control.

🧲Contactless operation with low maintenance

Wear-free sensing technology reduces maintenance and increases long-term reliability.

🔌Direct Mitsubishi M800/M80/E80/C80 CNC interface

Native Mitsubishi CNC compatibility enables fast, simple system integration.

🔇Excellent noise immunity from shielded housing

Robust shielding ensures stable signal performance in electrically noisy environments.

| Technical Data | Built-in encoder GEL 2444M | Built-in encoder GEL 2449M |

|---|---|---|

| General information | See GEL 2444 | See GEL 2449 |

| Module | 0.3 and 0.5 | 0.4 and 1.0 |

| Permissible air gap | 0.15mm ± 0.02mm (m=0.3) 0.20mm ± 0.03mm (m=0.5) | 0.20mm ± 0.02mm (m=0.4) 0.50mm ± 0.03mm (m=1.0) |

| Reference mark | Flag (N), Tooth (Z) | Tooth (Z) |

| Current consumption without load | ≤ 80mA | |

| Data transfer rate | 2.5 Mbps | |

| Power consumption without load | ≤ 0.5W | |

| Switch-on time | < 0.5s | |

| Working temperature range | 0 °C … + 70 °C | |

| Operating and storage temperature range | -30 °C … +105 °C | |