Small, flexible, robust and without integral bearing

The compact, high-resolution MiniCODERs have proven their value for speed and position acquisition in highly dynamic applications. They use their full potential when installation situations with little space require a particularly compact, robust and reliable measuring system. The magnetic measuring systems consist of a ferromagnetic target wheel and a scanning unit.

Without dedicated bearings, they are completely wear-free and maintenance-free. The optimised circuit and screening technique, and fully encapsulated electronics ensure reliable operation even in harsh environments.

High measuring accuracy and compact design have made MiniCODERs the most frequently used speed sensors in high-speed spindles in the world. More than 500,000 pieces are installed, among other things, in machines for high-speed cutting. They are suitable for speed and position detection in all highly dynamic applications and offer now also digital motor-feedback

Customised for you

We offer you individually developed MiniCODERs according to your requirements as well as precise target wheels with individual inside diameters. Choose features from our modular MiniCODER system such as output signal, target wheel module, design and interface and assemble your own bearing-less encoder kit. Our MiniCODERs are now also available with a serial Mitsubishi interface.

Intelligent linking of human, machine and workpiece

We have already implemented the „Industry 4.0“ market requirements in our MiniCODER family. Based on integrated microprocessors, the new MiniCODER generation sets new standards in communication and data preparation.

MiniCODER

Target wheels ZA, ZAN, ZAG and ZAZ

Target wheels ZA, ZAN, ZAG and ZAZ by Lenord+Bauer. L+B have over 40 years of experience in the manufacture of

GEL 2311 – Multiturn absolute rotary kit-encoder

The new GEL 2311 kit-encoder acquires the absolute rotor position precisely and can be flexibly adapted to any drive. They

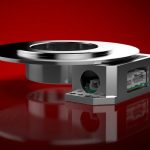

GEL 2449 MiniCODER

Contactless Measuring System A compact, configurable contactless measuring system combining a MiniCODER sensor and precision target wheel, delivering accurate speed,

GEL 2444 T- 2444 K – 2444D MiniCoder with TTL or SINCOS output

The GEL 2444 MiniCODERs are available in three variants, the GEL 2444-T sensor that generates a square wave output, the

GEL 2800 – Absolute rotary kit-encoder

The measuring unit comprises a magnetic sensor that provides an absolute single-turn position output based on the rotation of a

GEL 2432 – MiniCODER with SINCOS and TTL

The GEL 2432 MiniCoder is a sensor element that generates a sin/cos or square-wave output from a ferro-magnetic tooth-wheel or