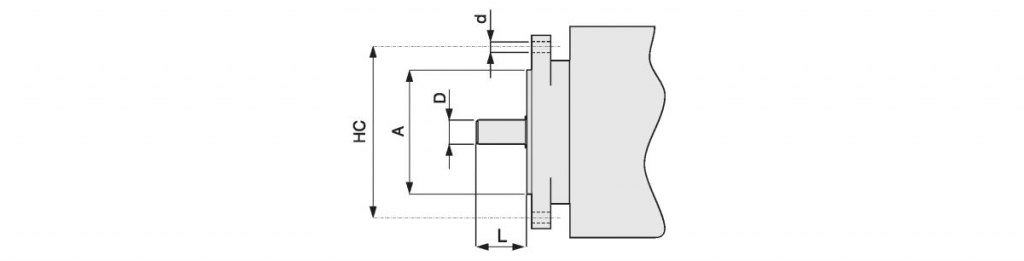

Key and keyway dimensions

The key and keyway dimensions for servomotors vary depending on the motor manufacturer and specific model. However, most motors have standardised dimensions for their keys and keyways. For example, the standard keyway size for a 3/8″ shaft is typically 3/32″ x 3/64″, while for a 1/2″ shaft, it is usually 1/8″ x 1/16″. The key […]

Bore and shaft tolerances

Bore and shaft tolerances are critical parameters for servomotors. Bore tolerance refers to the allowable deviation in the inner diameter of the motor’s mounting aperture, while shaft tolerance refers to the allowable deviation in the motor shaft’s diameter. These tolerances are essential to maintain the accuracy and precision of the motor’s movement and position control. […]

Motor Flange Table – quick reference of typical motor sizes

At Motor Technology we strive to supply standard product for any application you may have. Compatibility of differing motors becomes a major issue when you are looking for a replacement. To assist you in defining the motor size required, please use the table below. This is by no means a definitive list, but represents some […]

What is the smallest speed increment you can set on a servo motor?

In our Technical Answers series, we address questions that have been put to us by customers regarding their real-life applications. We’ve always sought to produce easy-to-understand articles that provide help and advice with every day servo and automation issues that will hopefully help all our customers. Our recent Back-to-Basics article on servo motors was a […]

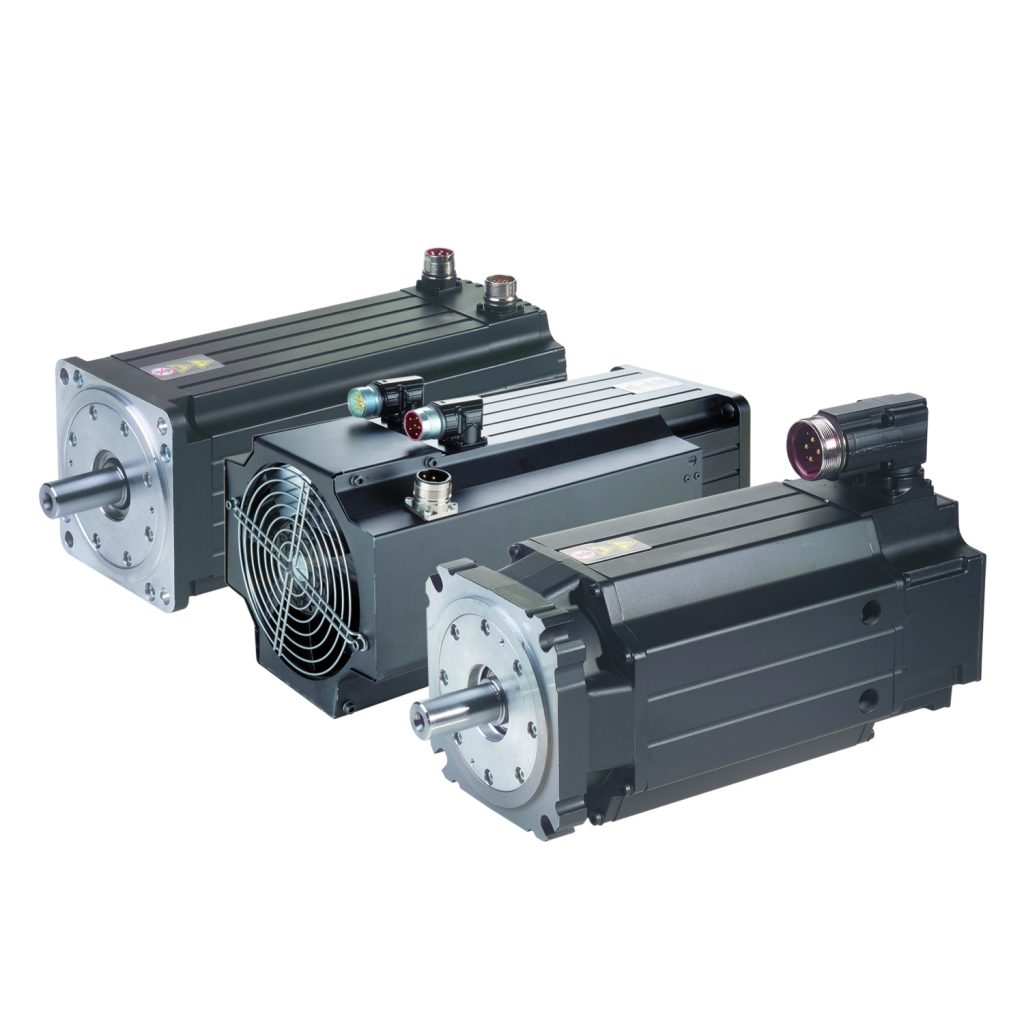

When a servo motor that’s big enough isn’t big enough

It might seem a strange statement, but yes, you read that right—there are certain operating conditions where servomotors that should be big enough for an application are actually too small! Too small that is in terms of their power rating, which for most applications is a perfectly acceptable way of selecting the right size motor. […]

Let us answer your technical questions

Servo and motion control technology can sometimes be complex, so to help demystify the subject and answer some of your trickier questions, we’re launching a series of short and simple articles as part of out new Technical Answers feature. We’d like to invite you to submit any question you may have on servo and motion […]

Know Your Duty Cycles

The International Electrotechnical Commission (IEC) has eight classifications for duty cycles to designate a motor’s operating conditions. It’s extremely important to know the differences and to note what mode of operation each rating refers to. When specifying a motor, it’s worth talking to a supplier that can give advice on such matters to ensure you […]

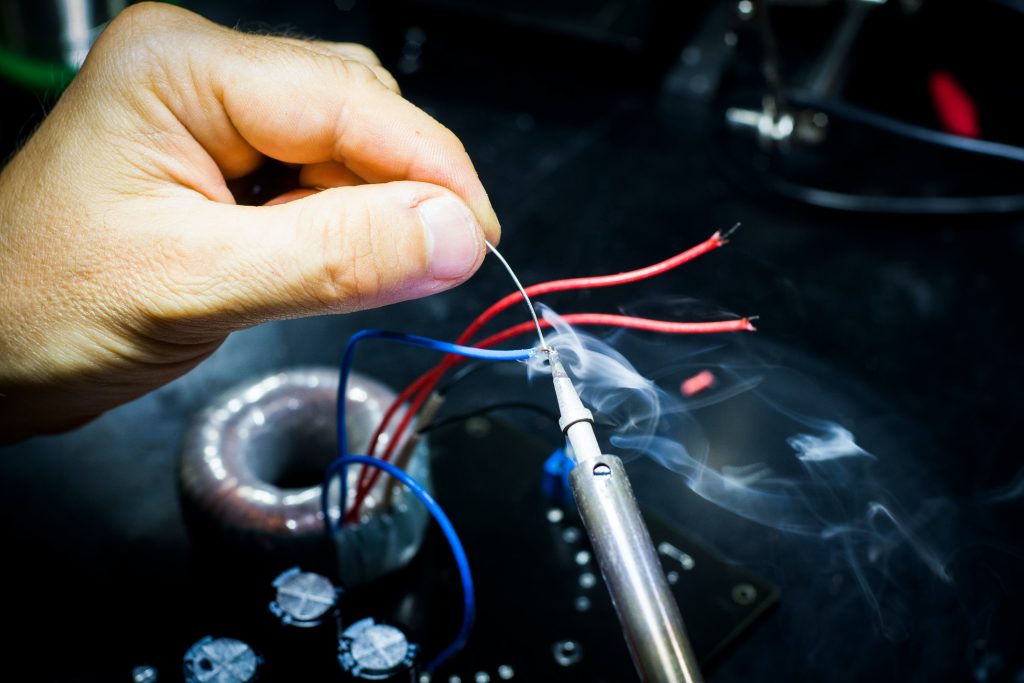

Do this before you send a servo motor to a repairer

If you’re sending a servo motor to a repairer you don’t know, it’s worth taking this one very simple precaution before you do. In fact, even if you know and trust the repairer, it’s still worth doing this just to be on the safe side. If you don’t and the repairer overlooks it then you […]

What do the modern 4 to 20mA loop and a pneumatic control system have in common?

The 4 to 20mA loop is currently the most common signal standard in modern use, but inherent within it is the ratio of 1:5 that was present in old pneumatic control systems. In the 4 to 20mA loop 4mA represents 0 and 20mA is 100%. On this scale 12mA, the halfway point between 4 and […]

Factfile: when are Steppers better than Servos?

Despite many claims to the contrary servo motors do not necessarily provide the best performance on every application. The structure of a stepper motor means that its positions are made up of discrete steps in its revolution cycle. If an application requires very good stand-still stability, like the positioning of a vision system for instance, […]

Glossary of components

Below is a list of typical terms used to describe some of the products and technologies we deal with. If you would like any more information or want to speak to one of our knowledgeable team members please call us on 0161 2177100 or click here Servo Drives AC Servo Drive, Amplifier, Brushless Servo Drive, DC Servo […]

Send us your technical queries and win a pen with super powers!

We’d like to invite all readers of Motor Technology News (MTN) to send us any questions on any industrial servo, control, positioning or general automation issues for our regular new feature Technical Answers. Our recent feature on cable colour coding, Understanding DESINA, made it into the May 2017 issue of Industrial Technology magazine and many […]

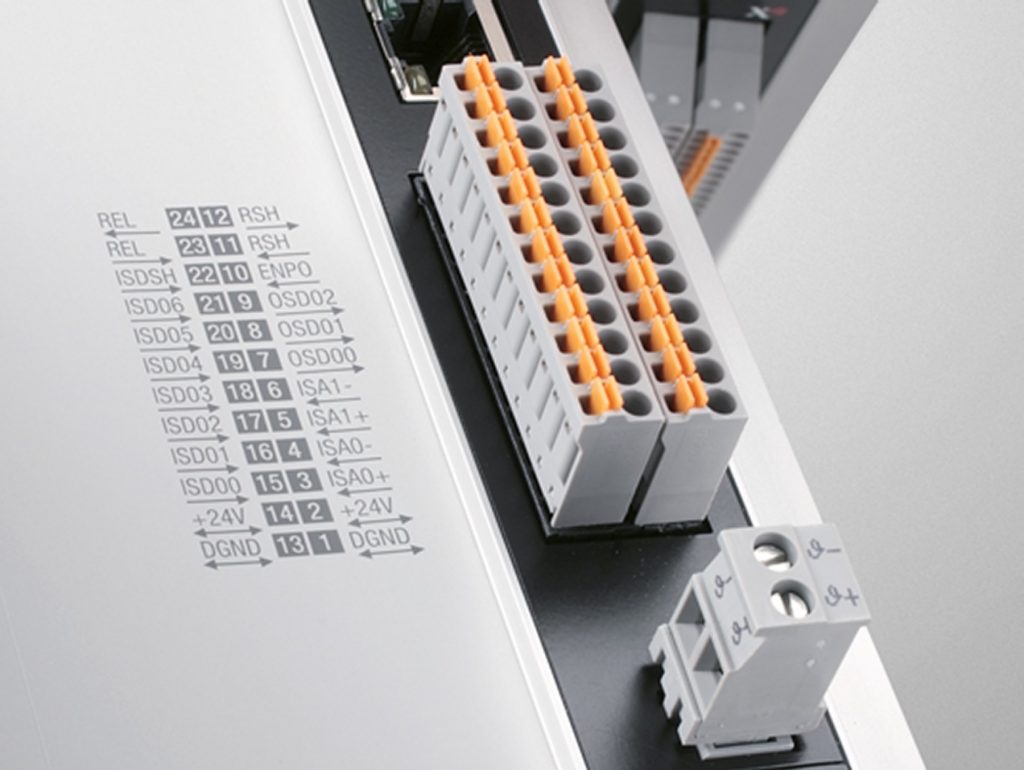

Cable colour coding – understanding DESINA

DESINA stands for DistributEd Standardised INstAllation Technology and is a standardisation for components used on industrial machines, including the drives, control systems and cabling. It’s a great idea with many benefits, but, where it relates to cable colour coding, the situation may be a little confusing and there’s room for error. The DESINA standard was […]