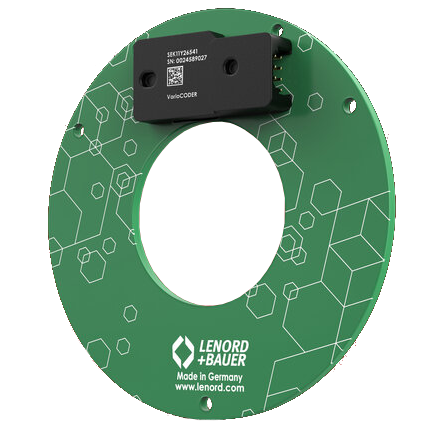

Compact Non-Contact Rotary Encoder

Compact, non-contact incremental encoder delivering reliable speed and position feedback in harsh environments, featuring magnetoresistive technology and ultra-shallow installation depth.

Key Features

📏 Compact Design

Shallow 11 mm installation depth for tight spaces.

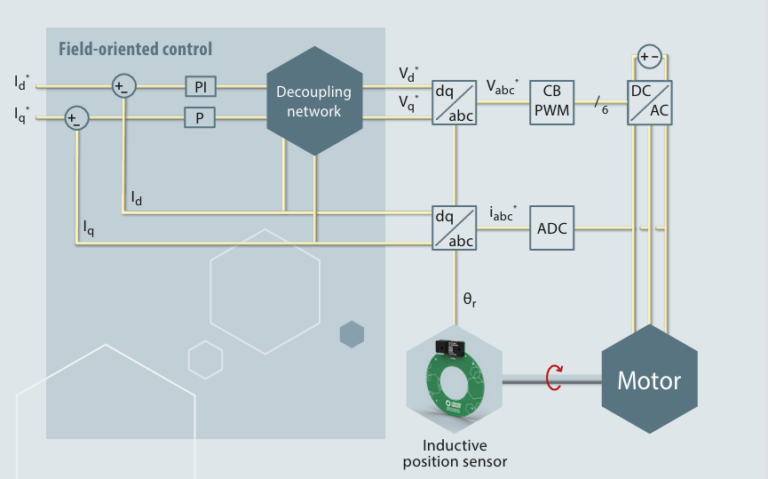

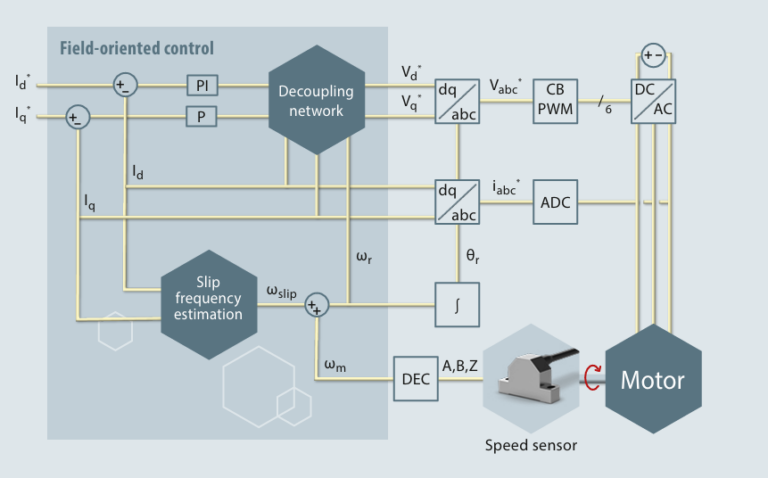

🎯 Reliable Signals

Magnetoresistive scanning ensures precise speed and position feedback.

🛡️ Rugged & Durable

Resistant to shock, vibration, dust, oil, and moisture.

🔧 Maintenance-Free Operation

Non-contact design eliminates mechanical wear for long-term reliability.

📈 High Performance

Supports up to 1024 pulses per revolution for accurate control.

🔌 Easy Integration

Industry-standard outputs compatible with PLCs and automation systems.