DynaBOX gearboxes have prooven themselves in servo motor applications over decades. The worm-wheel sets are designed specifically for precise, dynamic motion tasks. The materials, processes used and the unique worm-wheel design provide an over 90% contact pattern, giving the DynaBOX gearboxes in excess of 25,000 hours life expectancy and input speeds of up to 6000rpm.

The DynaBOX range is available in eight sizes from the 25mm shaft centre up to 110mm, with continuous torque up to 1000Nm and E-Stop torque up to 2200Nm.

They can be can be specified as either BASIC, MEDIUM or EXPERT units with lower than 10, 5 or 1 arc-minute of backlash respectively. They are also available with solid or hollow output shaft or a through-hole robotic flange.

They offer a space-saving design, are quiet / smooth running and maintenance free.

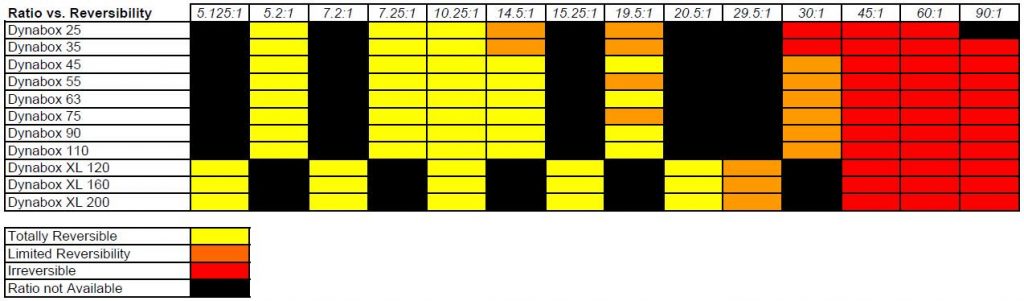

Depending on the geabox siye and ratio the DynaBOX gearboxes can be self-locking, potentially removing the need for expensive and space demanding holding brakes.

Mounting options

- Hollow shaft – keyed

- Hollow-shaft via taper lock (not on size 25)

- Single output shaft (not on size 25)

- Dual output shaft (not on size 25)

- Robot Flange (from size 45)

Dynabox range

- ratios from 5.25 up to 90:1

- centre / centre distances from 25 to 110mm

- continuous output torque to over 800Nm

- peak torque to over 2200Nm

- emergency stop torque to 4000Nm

Applications

- machine tools

- rotary tables

- industrial robots

- camera systems

- pick-and-place machines

- tracking systems

- semiconductor manufacturing

- simulators