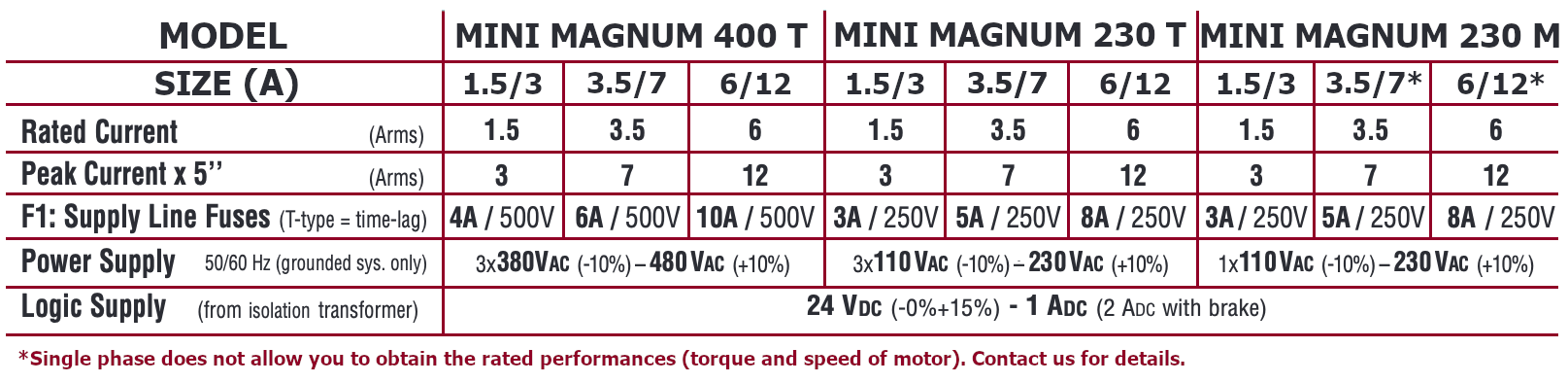

The fully digital Mini Magnum compact servodrive from Axor Industries measures just 66 wide x 201 high x 141deep (all in mm) and weights 1.75kg. The Axor Mini Magnum servodrives are suitable for driving AC brushless servomotors with encoder or resolver feedback. These units can operate directly on a single or three phase mains power supply ranging from 110 – 480V AC, depending on the type:

Mini Magnum 230M series

- single phase 110-230Vac (±10%)

- range up to 2kVA

Mini Magnum 230T series

- three phase 110-230Vac (±10%)

- range up to 2.4kVA

Mini Magnum 400T series

- three phase 380-480Vac (±10%)

- range up to 4.8kVA

The drives come complete with on-board power supply, EMC filter, dump circuit, detachable plug-in terminals for easy installation and the power stage is designed with latest generation of power IGBTs.

Typical applications include conveyors, medical equipment, textiles, packaging and converting machinery, feeders and positioners.

Operating Modes

- ± 10 VDC velocity control or torque control

- pulse/direction

- position control

- encoder follower and

- PLC function integration.

Features

- 110÷480 VAC power supply with EMC line filter and in-rush circuit on board

- Regen circuit with internal power resistor

- Speeder-One® software interface

- Parameter setting via keypad or RS232

- Cable screen connection directly to the front panel

- Optical isolation between power stage and signals

- Feedback modes – resolver (2-4-6-8 poles) encoder emulation (sw) – encoder (max 250 KHz) divisible encoder emulation (sw)

Options

- CAN BUS – CAN V2.0B + RS232 to CAN BUS multidrop

- CAN OPEN protocol implementations: DS301-V4.02 – DSP402-V2.0

- RS 485 interface, Mod Bus-RTU based, max. 230 kbps

- Encoder and resolver feedback version

- Increased regen capacity via external resistors

- Safety Enable Function (according to EN954-1/cat.3)

- Power-out dynamic brake function (with internal power resistor)

- HBD Holding Brake Drive Card

- Switching frequency 16 KHz