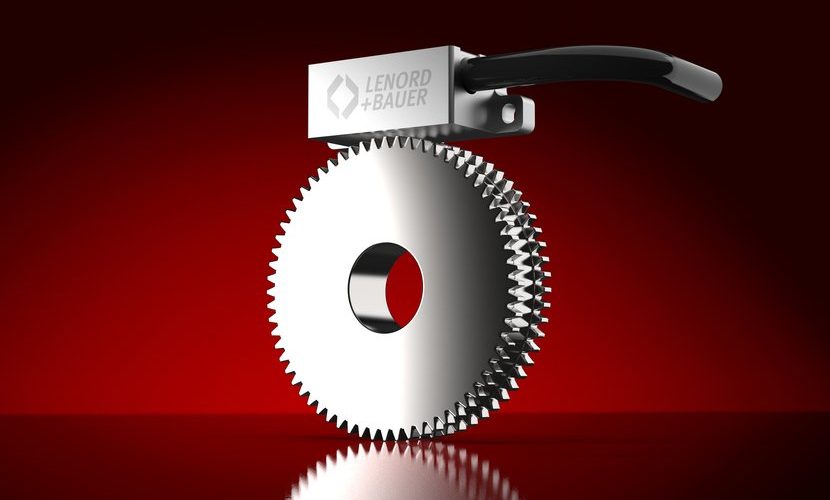

The measuring unit comprises a magnetic sensor that provides an absolute single-turn position output based on the rotation of a ferromagnetic measuring wheel. Typically the tooth-wheel is mounted directly on the drive shaft.

The GEL 2800 provides unambiguous position values at any angular position via an SSI or BISS interface. There is also an incremental signal for the rotational speed measurement.

The absolute position is available immediately after switch on, which makes a reference search routines unnecessary. Furthermore, the encoder kit undertakes a self-calibration; in this way the measuring system is also robust in relation to mechanical tolerances.

Due to the modular construction the system covers a wide range of shaft diameters, which significantly simplifies adaptation to the motor.

Features

- With additional incremental output

- Quick customer-specific adaptation

- Easy commissioning by on-site adjustment of scanning unit and measuring scale as well as parameter configuration by means of testing and programming unit

| Technical data | GEL 2800 |

|---|---|

| Fields of application | Drive technology, Special purpose machine construction |

| Supply voltage | 5 to 30 V DC |

| Temperature range | -40 °C to +105 °C (higher temperature range on request) |

| Incremental output | |

| Output signals | A+ / A- / B+ / B- |

| Output frequency | 0 to 200 kHz |

| Number of pulses (pulses per revolution) | 32,768 ... 262,144 configurable by division factor |

| Output signal level | HTL (TTL at UB = 5 V DC) |

| Synchronous serial interface | |

| Protocol | SSI (binary or gray code; others on request) |

| Maximum clock frequency | 500 kHz |

| Driver | RS 485 compatible |

| Preset | Set via input level or software command |