With the GEL 8240 cam-plate controller we have combined the Control Panel with the PLC to form a multifunctional compact control for a great variety of uses.

Lenord + Bauer GEL 8240 motion PLC

The Motion PLC combines a cam-plate controller, Control Panel, PLC and numerous inputs / outputs to a powerful automation unit.

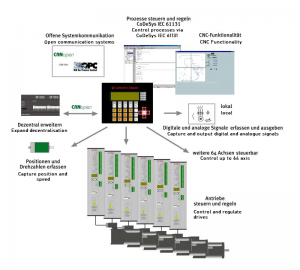

GEL 8420 example system layout

The integrated PLC in accordance with IEC 61131 and the CNC function with interpolated axes for path control offer compact solutions with minimum wiring.

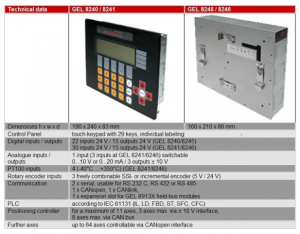

GEL8420 technical details

Up to 6 axes are controlled via the CAN-bus. Up to 3 axes are controlled via the integrated +/- 10 Volt interface.

Features

- Interpolates up to 24 axes in any combination.

- Advanced Multi-tasking Trio BASIC with up to 14 simultaneous processes.

- 150Mhz 32 bit Floating Point DSP

- 1 Mbyte application memory

- 256k word dedicated TABLE memory

- Individual Status LEDs

- Micro SD Card interface

- Compatible with all Trio Daughter Board interfaces.

- Fully integrates with MotionPerfect 2

- UL Approved

Highlights

- Controls up to 24 axes

- 14 simultaneous BASIC tasks

- Digital I/O – 8 IN + 8 IN/OUT

- Analogue I/O – 2 IN

- RS232 – RS485 – CANbus – MODbus