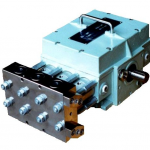

The Fuji-Techno Industries Super Metering Pumps offer precise delivery of liquid without the occurrence of cavitations (pulsation).

At the heart of every Fuji-Techno Super Metering Pump is a specially designed cam that controls the motion cycle of the three plungers.

The three plungers work in perfect equilibrium with each other. The timing of each plunger’s suction and discharge cycle is precisely controlled by the cam, so that the total liquid discharged from the pump is accurate and constant with no pulsations in the flow.

The plungers are designed to make different motions in six stages within one revolution of the cam and in harmony with each other. For example, the first plunger starts its discharge stroke with the cam at 0°, the second plunger starts at 120°, and the third at 240°. It is this unique operation that ensures constant flow with no pulsations.

An electric motor is used to drive the cam-shaft. The resulting motion of the plungers, creating suction and discharge cycles, effects the delivery of the liquid. The liquid being pumped enters and exits the pump head through suction and discharge valves.

Pump head materials

To meet the flexibility demanded by customers, Fuji-Techno have developed pump heads in various materials, both metal and metal-free. These include the standard stainless steel (316) type, stainless steel (316L), Hastelloy (C-22) and also Titanium metal versions, as well as the metal-free heads in PTFE and PEEK.

Seals and O-rings

To provide resistance to a variety of media the SMPs can be fitted with wide range of seals and O-rings. The plunger seals are typically UHMP, but PTFE versions are also available. The O-rings, as standard, are Viton, with options including Kalrez (also FDA compliant versions), EPDM, Silicone and H-NBR.

Plungers

The pumps are available with Ceramic, stainless steel (316) and Hastelloy/DLC (diamond like carbon).

Springs

The metal versions are fitted with a stainless steel (316) or Spron type springs. The metal-free versions are not supplied with springs.

Below you can fined a selector tool and links to the SMP catalogue and enquiry form. If you have any queries, please contact us.

Applications

• Chemical and Pharmaceutical processing

• Urethane and other resins

• Chromatography

• Explosives

• Food processing

• Film

• Spraying and coating applications

• Cosmetics

• Line mixing for liquids

• Feeding for extruder

• Water treatment

SMP range

Fuji Techno – HYSB Super Metering Pumps

Super Metering Pumps are precision instruments for feeding liquids accurately, at pre-determined volume, into a process or system. The accuracy

Fuji Techno – HYSC Super Metering Pumps

Super Metering Pumps are precision instruments for feeding liquids accurately, at pre-determined volume, into a process or system. The accuracy

Fuji Techno – HYM Super Metering Pumps

The HYM series super metering pumps (SMP) offer a solution for accurate pumping and dosing applications for laboratory trials, small

Fuji Techno – HYSD Super Metering Pumps

Super Metering Pumps are precision instruments for feeding liquids accurately, at pre-determined volume, into a process or system. The accuracy

Fuji Techno – HYSA Super Metering Pumps

The HYS-A series super metering pumps (SMP) offer a solution for accurate pumping and dosing applications for small scale production.