Unlike the MACK DRIVE multi-axis servo drive range, the AXOR’s MACK Indy is designed with low axis count applications in mind.

The drives are designed for a direct-on-line 230Vac, 50/60Hz single phase input and don’t require an expensive 24Vdc power supply for the logic circuit.

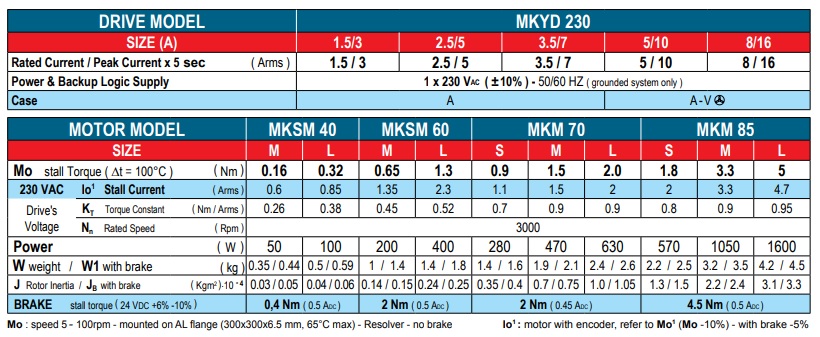

The MACK INDY range is complemented by a range of 10 motor variants, in 4 frame sizes, ranging from 0.16 to 5Nm stall torque, with rated speed of 3,000rpm.

The motors feature AXOR’s proprietary MACK serial encoder enabling the connection of motor and drive via a single, hybrid cable.

Standard Features

• In-rush and regen circuits on-board

• Speeder-One software interface with USB for setting and monitoring

• Single, hybrid, cable for motor connection

• Optical isolation between power stage and signals

• Operating frequency 8kHz

• Current loop bandwidth 2kHz

• Velocity loop bandwidth 200Hz

• Pulse/Clock and Direction control mode

• Serial encoder feedback

Options

- EMC line filter

- Differential analogue input

- CANbus

- EtherCAT

- ComCoder feedback (encoder with commutation tracks)

- Absolute multi-turn encoder feedback

- Emmulated Encoder Output

- STO Safe Torque Off, safety function

Configurations

- 1.5, 2.5 and 3.5 Amp versions (with x2 peak current for 5 sec) in 40mm wide housing

- 5 and 8 Amp vesions (with x2 peak current for 5 sec) in 56mm wide housing, with integrated fan

- maximum power output 2.5kW

Applications

• CNC robots

• XY guides

• Healtcare

• Textiles

• Conveyors

• Packaging

• Palletizing

• Carton / box manufacturing

• Printing machines

• Positioners

• Bar feeders

• CNC cutting and milling machines

• Woodworking machines

• Laser and plasma cutting

• Waterjet cutting

• Chemical plants

• Market garden automation

• Welding

• Sharpening

• 3D printers

• Sewing machines

• Upgrade replacement for stepper systems